Cocreating sustainability

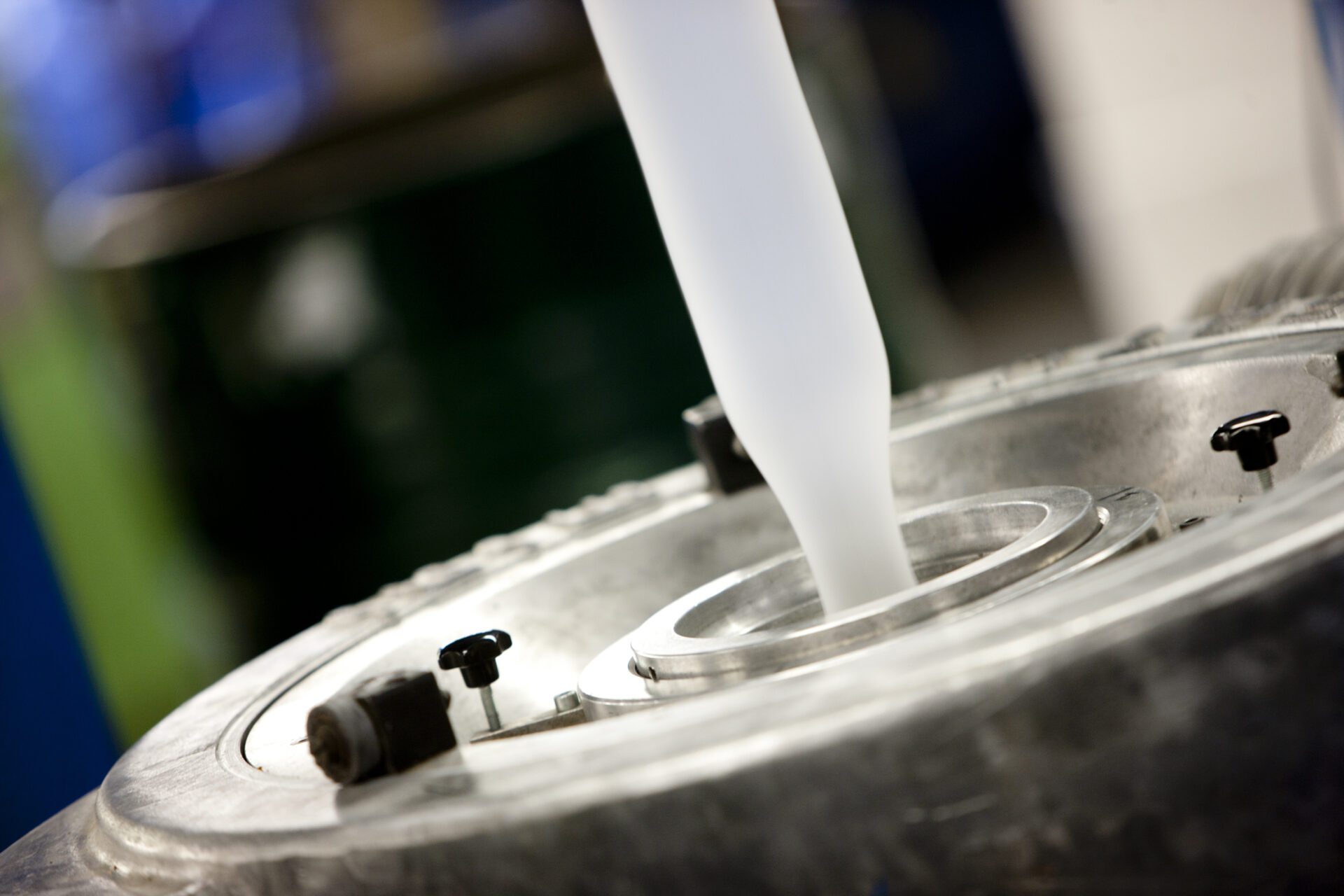

In 1959, Draka Interfoam started extruding polyethylene bags, used for packaging the mattresses they produced. At that time, producing mattresses was their core business. Afterwards, the range of films was expanded and other industrial packaging was added. Below you can read about the complete company history, until the present day:

Plasthill produces and supplies a full range of specialized, flexible films and packaging in paper and plastic variants. The group consists of seven manufacturers, ten production sites, independent research lab, inhome reprographics and more than 750 professionals with huge experience! We would like to unburden you; from design to packaging production and implementation.

In our digital product environment; innovation and sustainability meet in the diverse range of flexible custom packaging solutions.

With a balanced mix of knowledge and passion for the packaging product, we specialize in developing advanced packaging solutions which not only meet but exceed the demands of today’s dynamic markets!

In our digital market environment, visitors have reached the destination for customized packaging solutions in a broad spectrum of sectors. We divide these into main areas food, non-food and agri/horticulture.

Discover the Plasthilldetailed market selections meticulously tailored to specific industry needs. With a focus on customization and innovation, you will discover the perfect packaging solutions uniquely designed for your business.

Experience our expertise in packaging for different markets – your journey to customized solutions starts here!

Meet Plathill’s solutions: our online hub – dedicated to the unique properties of packaging. Discover innovative, sustainable customized solutions for a variety of industries. Consider flexible packaging options designed for ultimate product protection and environmental responsibility.

Help us shape a greener, more efficient future – together we can make IMPACT! A few examples:

Learn more about our latest developments, publications, blogs and articles with third parties in the Plasthill newsroom.